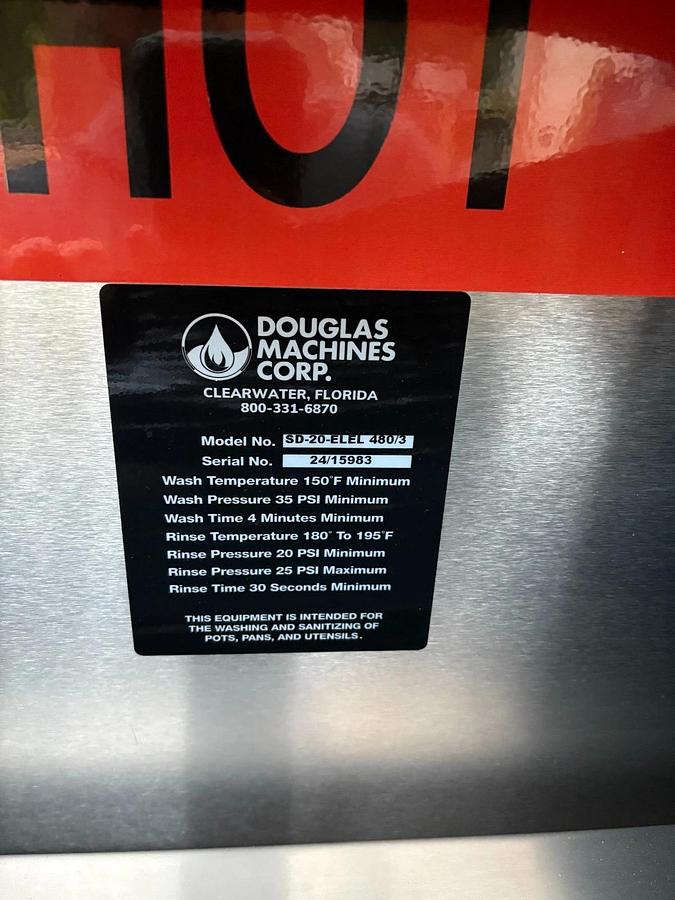

Brand new - Brand new Douglas / Display Specialties SD-20-ELEL Pan Washer -SCRATCH AND DENT CLEARANCE

Brand new - Brand new Douglas / Display Specialties SD-20-ELEL Pan Washer -SCRATCH AND DENT CLEARANCE

C$28,560 (CAD)

Available quantity:1

Description

Brand new scratch and dent unit that only had a small cosmetic issue w/ a leg. Still in factory crate ready to install!

480 Volt - 3 Phase, 40 Running Amps, 50 Amp Minimum Service

Breaker

Designed for batch type operation where the wash rack is loaded

with items to be cleaned. After the door is closed, the short, medium

or long wash cycle is selected then which initiates a 150° F.

recirculating detergent wash followed by a 180° F. freshwater

sanitizing rinse. The sanitizing rinse water flows into the

recirculated wash tank for reuse and freshening causing excess

water to overflow to drain. A buzzer and unload light indicate cycle

completion. The door is then reopened for unloading and reloading

for the next cycle. Booster heaters maintain proper operating

temperatures.

CABINET 50” wide x 36” deep x 71 1/8” high (86 1/8” overall clearance height

with door open, 102” with gas heated rinse tank). Door Opening: 40”

wide x 28” high. Wash Chamber: 38 3/4” wide x 26 3/8” deep x 25

1/2” high. Constructed of #16 gauge, #304 STAINLESS STEEL with

a #3 finish. All seams are tig welded. Seams, where needed for

watertight construction, are continuously welded. All other seams

are stitch welded for strength. All welds are cleaned inside, cleaned

and buffed outside. Optional continuous welds in lieu of stitch welds

available.

DOOR Front loading, split type design for easy loading and unloading. The

top half of the door system rises while the lower half folds down to

create a space-saving drain table. Door is interlocked with limit

switch to prevent machine operation while door is open. Constructed

of #14 and #18 gauge, #304 STAINLESS STEEL with a #3 finish.

RECIRCULATING WASH

TANK

Constructed of #14 gauge, #304 STAINLESS STEEL, heated by 12

KW electric immersion heaters (infrared gas, live steam or steam coil

options are available). Complete with low water protection,

automatic fill, 1 1/4” NPT overflow connection, 1 1/4” gate drain

valve, thermometer, pressure gauge and is thermostatically

controlled. 36 gallon tank capacity (27 if gas heated), sloped to

drain. Optional automatic pump operation for elevated drain

locations (42" high max) is available complete with 1/14 H.P., 120

volt, single-phase drain pump. With this option, wash tank

completely drains when power is turned off.

WASH PUMP Closed coupled centrifugal wash pump, bronze fitted with cast iron

casing. Complete with 7 1/2 H.P. ODP motor (optional TEFC or wash

down duty motors available). 480 Rated for 120 gallons per minute at 35 to 45 PSI.

Optional STAINLESS STEEL wet end available.

2

ROTATING WASH HUB

ASSEMBLY

Water driven, STAINLESS STEEL spray arm assembly with

STAINLESS STEEL jets, removable end caps and hand operated

quick release mechanism for easy cleaning and reassembly.

FILTRATION Perforated STAINLESS STEEL basket type. Double filter system for

increased effectiveness and easy cleaning without emptying wash

tank.

SANITIZING RINSE

TANK

Constructed of #14 gauge, #304 STAINLESS STEEL, heated by 12

KW electric immersion heaters (infrared gas or steam coil options

are available). Complete with thermometer, pressure gauge and is

thermostatically controlled. Uses 5.6 gallons per 30 second cycle at

20 PSI and has a 10 gallon capacity.

RINSE PIPING #304 STAINLESS STEEL tubing with brass compression fittings and

full cone rinse jets. Optional STAINLESS STEEL fitting and jets are

available.

ELECTRICAL

ENCLOSURE AND

CONTROLS

Electrical enclosure is UL 12 STAINLESS STEEL with Sq. “D”

components. Optional disconnect switch with safety lockout is

available. Includes 120 volt control circuit and motor starters. Digital

Control and Information Center consists of push pad operation of

“POWER ON”, “SHORT, MEDIUM or LONG” wash cycles. Also

included is a digital display which indicates time remaining, cycle

indicator lights and a buzzer to indicate full cycle completion. The

display along with the push pad can also be used as a diagnostic

center by displaying error codes for ease of troubleshooting.

Moisture resistant gauges measure temperatures and pressures for

wash and rinse cycles. Optional UL 4X STAINLESS STEEL electrical

enclosure with three way selector switch, push button controls and

adjustable timers or Schneider Modicon PLC with Magellis 5.7 color

operator interface touch screen including ethernet and data logging

capabilities in lieu of Digital Control and Information Center. Washer

will be wired in hard aluminum conduit and tested prior to shipment.

EXTERNAL RINSE HOSE Externally mounted rinse hose with spray gun for easy cleaning and

maintenance of the machine.

STEAM EXHAUST VENT Steam exhaust vent 6 3/4” I.D. consisting of #16 gauge rolled collar,

for 6” PVC pipe connection, bolted to the top of the machine.

Machine pre-wired with control timer for the addition of a fan.

OPTIONAL EXHAUST

FAN

Draft inducer fan side mounted on exhaust duct to extract excess

steam after sanitizing rinse cycle. 1/40 H.P. ODP motor, 110 volt, 1

phase, 1550 RPM, rated for 250 CFM at .05” static pressure.

Optional fan with STAINLESS STEEL housing and blade with 1/2

H.P. 3 phase motor is available.

480 Volts

RACKS Customized to hold your specific items. Standard bakery racks

include utensil basket with two (2) hold-down lids and two (2)

bun/sheet pan inserts designed to hold ten (10) pans each.

Constructed of STAINLESS STEEL rod, mig welded.

3

CONNECTIONS Water Inlet: 3/4” NPT, 120° F. at 20 PSI

Drain: 1 1/4” NPT

Overflow: 1 1/4” NPT

Electrical: Single-point connection.

UTILITIES See attached Utilities Chart for service requirements specific to

various combinations of wash and rinse tank heating. Calculations

are based on a room temperature of 72° F.

ELECTRIC HEATED

WASH TANK, ELECTRIC

HEATED RINSE TANK

The Douglas SD-20-ELEL Pan Washer, available in our scratch and dent clearance, offers an excellent opportunity to own a reliable industrial cleaner at a reduced price. Although classified as new, minor cosmetic imperfections may be present. This model is engineered to handle high volumes of pans efficiently, making it ideal for commercial kitchens and institutional facilities that demand consistent cleaning performance. The SD-20-ELEL features advanced washing and rinsing systems designed to ensure thorough cleaning of various pan sizes and styles. Its robust construction ensures durability and longevity, even with constant daily use. This washer is designed with user-friendly controls for easy operation, minimizing training time and maximizing efficiency. Its energy-efficient systems help reduce operational costs while maintaining high cleaning standards. This model is a great choice for those looking for quality and performance without the premium price tag typically associated with brand-new industrial washers. Despite minor cosmetic blemishes, the SD-20-ELEL performs as intended, offering the reliability and effectiveness Douglas Machinery is known for.

Specifications

| Manufacturer | Douglas Machinery |

| Model | SD-20-ELEL |

| Condition | New |

| Stock Number | RX-0126-13499 |